Brochures/Visuals

Plastic & the Automobile Trifecta Fact Sheet

Learn how lightweight plastic and polymer composites play a critical role in today’s automobiles.

Download PDF

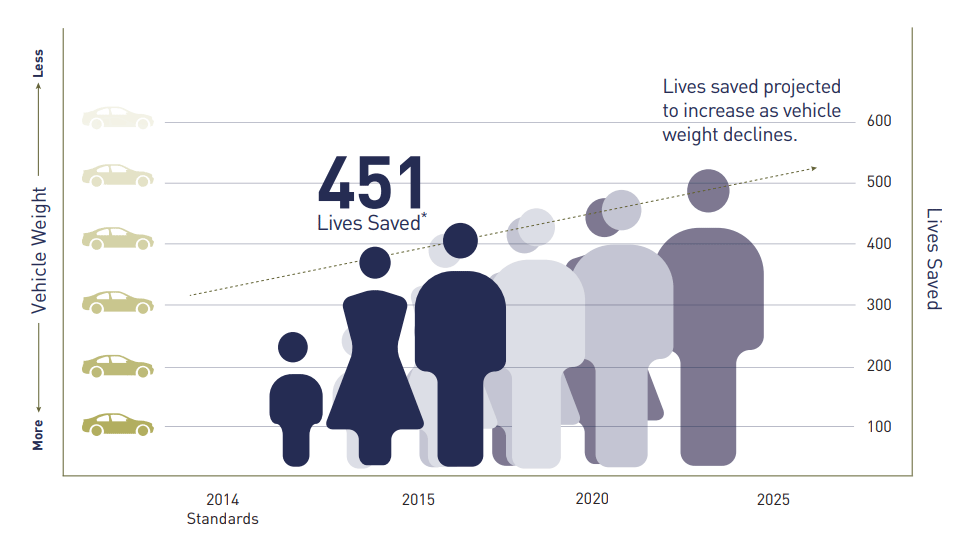

Infographic: Modeling Shows Automotive Material Lightweighting Saves Lives

New advocacy graphic demonstrates the roll of plastics and composite lightweighting in maintaining safety. Research shows that as cars lightweight, weight reductions alone can reduce traffic fatalities. More aggressive weight reductions than needed to achieve current proposed CAFE standards can save even more lives.

Download PDFAutomotive Research on How Lightweight Plastics Enhance Safety

Vehicle Front-end Safety

- Physics in the crumple zone demonstrate how less stiff materials, like plastic, can help prevent injury and save lives

- Using plastics in auto “glass” can lightweight a vehicle and help prevent passenger injuries

- Composite driveshafts can increase torque and can help prevent injuries

- Plastic composite structures in the front end of a vehicle can lightweight without compromising safety

- Plastic headlamp lenses reduce weight and reduce lens breakage, which can improve nighttime visibility and safety

Vehicle Interior Safety

- Using plastic to consolidate parts in door modules can reduce weight and maintain or improve side impact safety

- Plastic hybrid materials found throughout the Porsche Carrera GT make it light in weight and structurally strong

- Plastic can be incorporated in energy absorbing steering columns to help reduce vehicle weight and enhance driver safety

- Lightweight plastic foams can add strength to automotive body cavities and increase occupant safety in vehicles

Vehicle Exterior Safety

- Composite fuel tanks lightweight vehicles allowing alternative fuels to be carried onboard

- Plastic fuel tanks can decrease vehicle weight and incidence of corrosion

- Using lightweight plastic to lower the center of gravity can help increase stability and decrease rollover tendency

- Lightweight plastic fibers can have added strength but enough ‘give’ to enhance pedestrian safety

- New auto safety research evaluates impact of size and weight on accidents

Investigation of Opportunities for Lightweight Vehicles Using Advanced Plastics and Composites

Pre-competitive research details opportunities for lightweighting a Silverado truck by nearly 1,000 pounds, using plastics and composite technologies available today.

Learn More

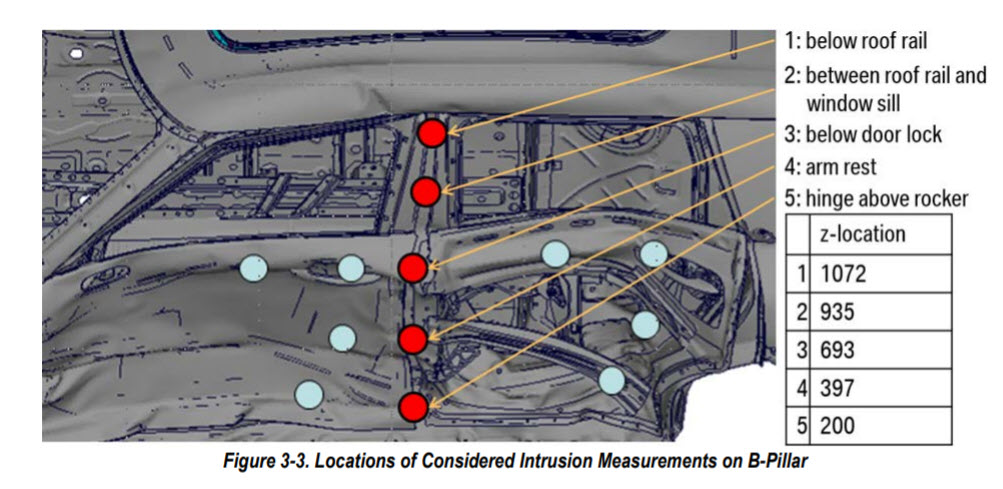

NHTSA High-Performance Computing Study on a Carbon Fiber Automotive "B-Pillar"

Carbon Fiber reinforced plastic (CFRP) material is becoming one of the preferred solutions for vehicles to achieve overall weight reduction in order to meet fuel economy and emission standards while maintaining safety requirements and offer several advantages, including higher levels of ductility and specific energy absorption, rapid processing, and recyclability and reuse.

The objective was to investigate the tools for design, optimization and manufacture of carbon fiber thermoplastic materials for vehicle side frame structures (B-pillars) subjected to high-velocity side-impact crash loading. The study demonstrated a carbon fiber thermoplastic B-pillar offered 60 percent weight savings over the metallic baseline and satisfied the side-impact crash requirements. Also, for safety, the dynamic impact and crush response of the B-pillar was adequately modeled using computational tools.

Learn MoreGrab These URLs & Share These IIHS Safety Videos

“https://youtu.be/WQMQQFU5_aQ”

“https://youtu.be/BT3Y7cZIlpo”

Innovations in plastics are helping make cars light, energy efficient and safe

- A new manifold that increases horsepower 33%.

- A front grill that saves weight and 50 of former tooling costs.

- A single plastic part that reduces the need for 27 extra parts.