Recycled Carbon Fiber-Reinforced Epoxy Battery tub

Lighter. Stronger. Smarter. This is the mantra of Clemson University’s 31-student team which is advancing sustainable vehicle design using engineered and fiber-reinforced plastics. Clemson students are completing an ultra-efficient concept vehicle designed for the year 2035 – and a big part of their design takes advantage of engineered and fiber-reinforced plastics.

About Deep Orange 11

The 2035 project is part of Clemson’s Deep Orange program, which pairs graduate students with industry leaders to address a “grand challenge” by designing, building and validating a prototype vehicle. Located at the Clemson University International Center for Automotive Research (CU-ICAR) in Greenville, South Carolina, Deep Orange students have access to state-of-the-art, automotive-testing and advanced-materials equipment to build and test their concept car.

For its 11th iteration, Deep Orange students are advancing solutions to environmental, economic, and social concerns a step further, designing their vehicle to be sustainable not only during manufacture and operation, but throughout the end of its usable life. Their goal is to push automotive and mobility innovation beyond the current landscape. Using advanced materials – from recyclable plastics to reclaimed carbon fibers – students’ design decisions have been driven by materials’ effect on the final sustainability index.

The result? A concept vehicle that combines innovative ideas, novel structures, and low post-service-life impact to best serve the urban passenger and society of 2035.

Choosing sustainability as their project focus makes plastics an excellent choice, due to plastics’ high strength-to-weight ratio and re-processing opportunities at the end of the vehicle’s life. As a result, the Deep Orange 11 prototype includes 18% plastics and composites by weight – nearly double the 10% market average.

The Process

The Deep Orange 11 team began their two-year, six-phase development process in Fall 2018, starting with classroom learning about the auto industry, manufacturing operations, systems integration, and project management for a highly complex project. Vehicle prototype design began in early 2019, when students organized into teams based on subsystem responsibility – autonomy, body-in-white, interiors, powertrain (internal combustion engine (ICE) and electric), and vehicle dynamics.

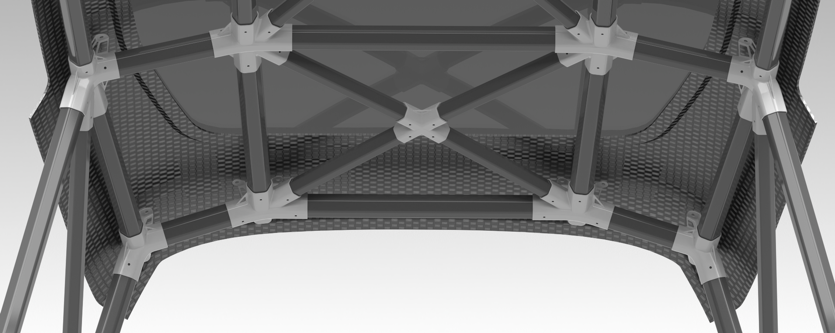

The team has discovered that engineered and fiber-reinforced plastics allow for entirely new structures and designs, making way for considerable weight savings and improvements at every level. For example, students designed a novel tube-and-node upper-frame architecture made with carbon fiber-reinforced plastic (CFRP), allowing lighter components plus greater reconfigurability and repairability.

Tube-and-Node Frame Structure

Designed to last for one million kilometers (about 621,000 miles), the students planned their vehicle for easy repair and reconfigurability. Using 3D-printing, damaged interior and exterior panels can be removed and replaced without affecting nearby panels’ integrity.

The team found other ways to enhance vehicle sustainability. The autonomy team built a platooning (close-proximity driving) feature to minimize wind resistance, and a travel planner to discover the most efficient route. Regarding propulsion, both electric motor and ICE (to extend travel range) are included; the ICE uses a low-carbon fuel to minimize environmental impact.

Throughout the process, the Deep Orange 11 team has relied on their sponsors and partners for technical expertise, mentorship, and components, as well as valuable test data and feedback rooted in real-world experience. With ExxonMobil and Honda R&D Americas headlining the sponsor group, the team has had top-notch technical expertise to draw upon. However, partners have made sure the team has worked and learned, rather than providing out-of-the-box solutions to design challenges.

Technology Breakthroughs

Armed with advanced thermoforming tools and 3D printers as well as faculty guides and industry expertise, the team has cut weight in their prototype by redesigning components to use advanced materials and novel designs in several key areas.

- Process and Material Selection: Students chose to thermoform the exterior body panels and 3D-print interior trim. They’ve found that among the biggest advantages of composite materials are their high strength-to-weight ratio, plus process and design flexibility that speeds development and lowers cost.

- Tube-and-Node Upper Frame Architecture: Students designed a novel, multi-material frame structure that combines the rigidity of carbon fiber with the versatility of metal-additive manufacturing for an ultra-lightweight (76kg) load-bearing tube-and-node geometry. Each node has a unique design – well suited for metal 3D printing – in order to snugly connect a series of hexagonal carbon-fiber tubes with structural adhesives that support the CFRP roof frame, exterior body panels, interior trim, closures and electronic sensors.

- Recycled Carbon Fiber-Reinforced Epoxy Battery Tub: Since high voltage battery lines have to be kept isolated from the vehicle’s low voltage electric circuit, the electrical insulation properties of carbon-reinforced composites are an advantage over metal counterparts. Students fabricated the tub using recycled carbon fiber with flame-retardant epoxy resin, which combined weight savings, electrical insulation, and corrosion resistance.

Body frame structure and panels

After transitioning to remote work in March 2020 due to COVID-19 restrictions, students returned to the CU-ICAR prototype lab in early May and are on schedule to complete the vehicle build in August 2020. Completing this two-year project will also mark the end of their Masters in Automotive Engineering degree program at Clemson University.

Look for more details in a future blog post about the unveiling of the Deep Orange 11 sustainable-by-design concept vehicle.

Numbers

- 76 kg: total weight of the tube-and-node body frame supporting the CFRP roof frame, exterior body panels, interior trim, closures, and electronic sensors for autonomous driving

- 12kg: total weight of the CFRP roof frame, which houses a large panoramic sunroof

- 33%: weight savings (compared to steel) by using structural adhesives to bond the Al 6061 alloy floor to the lower frame

- 45%: battery-tub weight savings due to using recycled, carbon fiber-reinforced epoxy with steel cross members

Advanced-Material Components

- Upper frame structure: Hexagonal CFRP tubes and stainless-steel nodes

- Exterior Body panels: PETG/ABS thermoplastic sheets

- Interior Body panels: 30% glass-filled Polypropylene

- Battery Tub: Recycled carbon fiber-reinforced composite

- Roof frame: Carbon fiber-reinforced composite

- Interior seat cladding: 30% glass-filled Polypropylene