Hint: Plastics Are Driving Innovation, Safety, Fuel-efficiency, & Sustainability

What’s one of the most hi-tech computers you use? Chances are it’s the car you drive or rideshare.

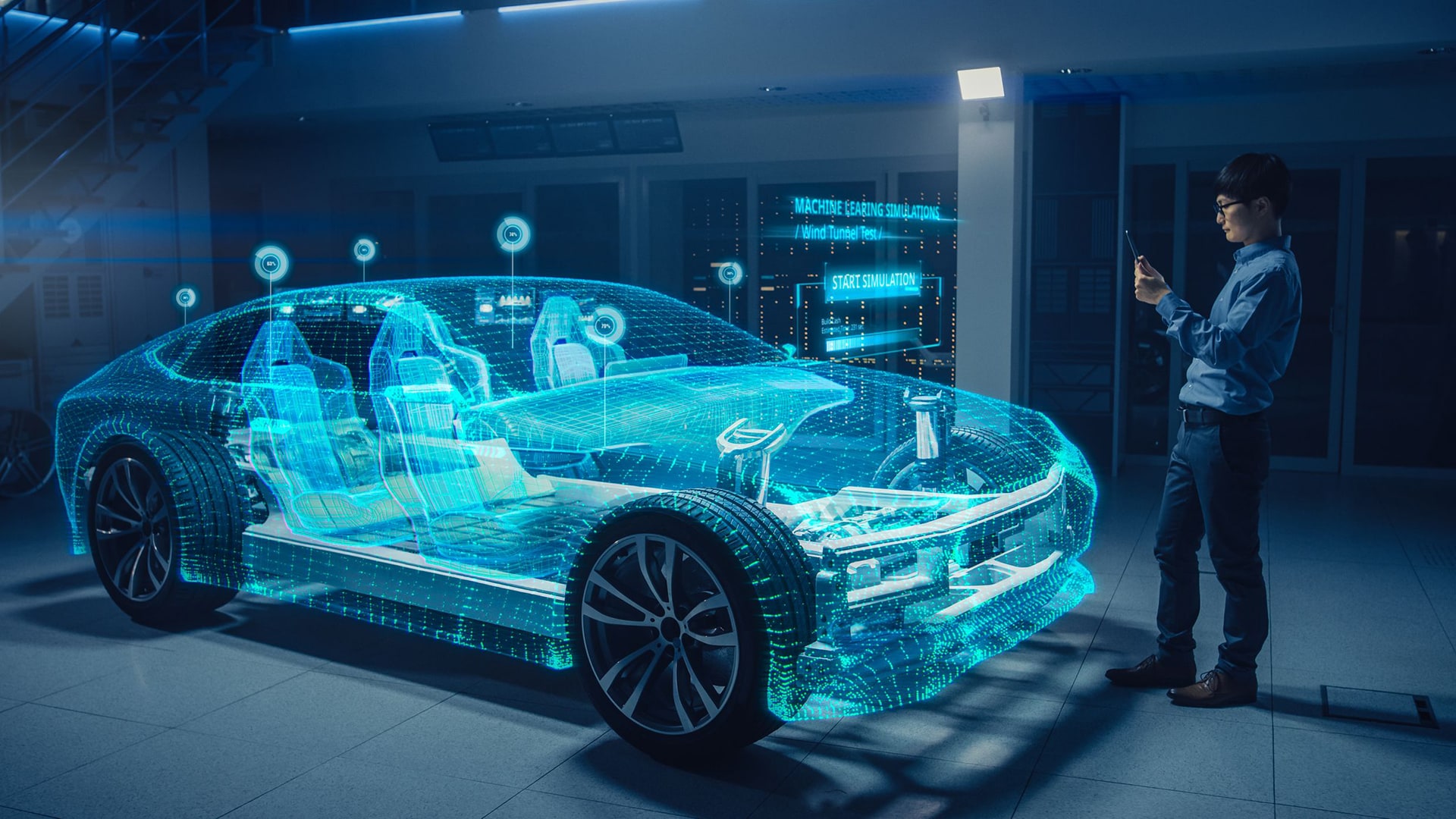

The modern car is a technological marvel, a remarkable feat of engineering packed with systems for propulsion, safety, comfort, entertainment, and environmental protection.

And cars of the future? You ain’t seen nothing yet. Our cars have evolved from gas guzzling clunkers to today’s sophisticated ride. And now they’re transforming into low emission, connected, autonomous, and more sustainable mobility makers.

And so much of that is enabled by plastics. Today’s cars on average are made up of about 50% plastics by volume but only 10% by weight. Lightweight plastic auto parts help improve fuel efficiency, make our cars safer, and leave a lighter environmental footprint than available alternatives. And now plastics and plastic composites are ready to lead us into the future of mobility.

To reach that future, carmakers are continuously rethinking their approach to building a more advanced, connected, and sustainable car… relentlessly looking for new ways to drive innovation.

To help carmakers in this process, America’s plastic makers offer the ACCESS Framework: a roadmap to promote Autonomy, Connectivity, Circularity, Electrification, Shared mobility, and Sustainability – or ACCESS – in our cars and trucks.

Modern, advanced plastics and plastic composites will play an outsized role in enabling these evolutions/revolutions in mobility. Leading to safer, more efficient vehicles. And just a really fun ride.

The winner? You and the planet.

Here’s a glimpse:

- Autonomous – Lightweight plastics will help offset the additional weight needed for automated driving systems – e.g., sensors, electronics, biometrics, radar, and LiDAR (light detection and ranging). Plus, they’ll help integrate these systems into vehicles and provide new and flexible interior configurations for passengers.

- Connected – High-value connectivity features that allow vehicle-vehicle and vehicle-infrastructure communication – e.g., artificial intelligence features, 5G network, touchscreens, and haptics/3-D touch – will be protected and shielded by plastic sand seamlessly incorporated into vehicles.

- Circular – Carmakers have set goals and are implementing initiatives to improve the circularity of their operations, including their use of plastics. Plastic makers are working together – and with part/component suppliers and carmakers – to help the auto industry transition toward a more circular economy.

- Electrified – In addition to light-weighting benefits mentioned above, specialty plastics help protect the battery pack and guard against fire hazards from EV batteries, contributing to safety. Advanced plastic-based battery separators for lithium-ion batteries can boost battery power by up to 30%, enhance temperature stability, and extend electric vehicle range under a single charge. And durable plastics will help us build our nation’s network of charging and refueling stations.

- Shared – Ride sharing and subscription vehicles with high usage rates will rely on anti-odor, self-cleaning, and highly durable plastics for interiors. Shared vehicles in particular will require tamper-resistant plastic enclosures to help reduce damage to expensive vehicle electronics… without impeding radio signals.

- Sustainable – Plastics and composites companies are working with carmakers to reduce environmental impacts, in part through developing lightweight components that improve fuel economy, as well as through designing for end-of-life recyclability. And increasing numbers of carmakers are using recycled plastics to make multiple car parts, from seat cushions and insulation to critical engine components.

Continue to visit AutomotivePlastics.com to learn more about the steps America’s plastic makers are taking to build a circular economy for plastics and create a more sustainable future.

And check out our Roadmap to Future Mobility.

Originally published on plasticmakers.org